Happy new year everyone! I’m pretty sure you have some resolutions for 2026 and if you're thinking about launching an apparel brand this year, you probably have many ideas in your mind but if you already run an apparel brand or work in fashion, you’re probably thinking about what’s next. Custom embroidery is getting really popular nowadays. People want outfits that look attractive and unique, last longer and look so much better than printed designs.

In this post, we will discuss custom embroidery trends for 2026 so you can plan your next collection the right way. Let’s start.

Have you ever waited for an embroidered logo and felt nervous when the machine started stitching? That quiet moment when you hope everything turns out right but deep down, you are not sure. Many people experience this. The logo looks perfect on the screen but once it is placed on the fabric, everything goes wrong. Stitches look messy, threads break, edges lose their shape and small text becomes difficult to read.

This doesn't happen by chance. In most cases, the problem starts with how the logo was digitized. A logo is not just a picture. It carries a brand name, a business image and of course builds trust. Even one stitching mistake can make a logo look unprofessional on caps, shirts, jackets and more.

This is where the question arises: which one is good for logos, manual digitizing or auto digitizing? well this guide is specially for you. In this guide, you will understand every point clearly. Let's start understanding this mystery with the help of this guide.

Guys are you enjoying winter? Winter gives us calm and relaxing vibes, a comforting feel. Snowy or cold mornings, slow evenings and warm clothes give us next level comfort, they also bring new creative ideas, for the winter season, especially for embroidery. Winter themed embroidery designs are becoming more detailed and more common on clothing and home decor items. Snowflake patterns, classic winter trees, and cozy seasonal designs turn plain fabric into a unique and special. Winter designs give different ways to create embroidery designs that feel warm and visually appealing.

Just a few days are left in Christmas and everyone is super excited about the lights, the music, the cookies, and of course, the gifts. There’s just something extra wonderful when a present is specially made with embroidery machines and has beautiful embroidery designs on it. That little stitched design turns a plain jacket, caps, shirt or stocking into something that feels truly personal and full of love.

This is the perfect time to get stitched Christmas embroidery designs for gifts. People absolutely love receiving stitched items, and these designs are some of the most popular ones for 2025. If you’re finding designs for your family, friends or even for yourself, here are the 25 best designs that will make your gifts unique.

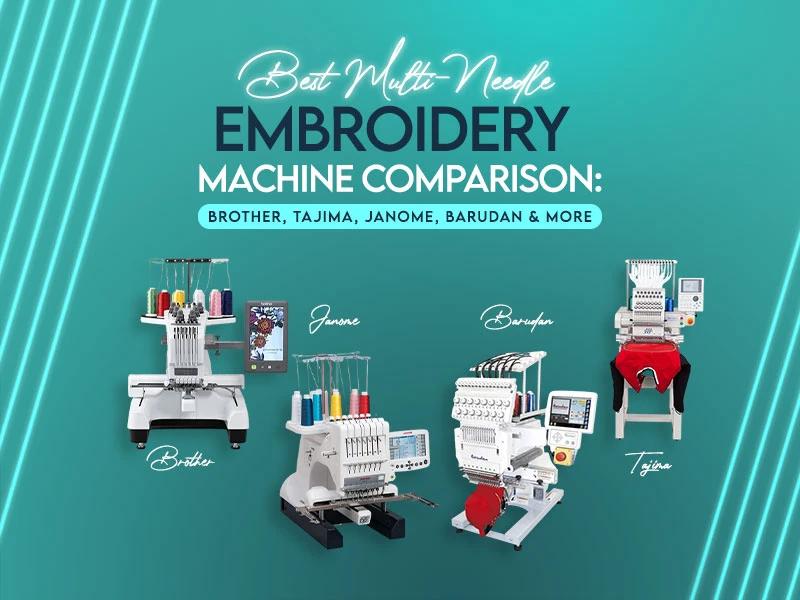

When you see multi-needle embroidery for the first time, the thoughts that come to mind are speed, accuracy and price. Beginners start with single-needle machines and then they realize how difficult it becomes to handle color changes, detailed logos, caps, jackets and thread adjustments. A multi-needle machine solves these issues by giving you more control, speed and smooth stitching that doesn't break your flow.

Guys you try to convert an SVG file into embroidery designs for the first time, the expectations are that the stitches will form exactly like the artwork looks on screen. In reality, the lines shift, the fill areas look uneven, small curves overlap or the machine doesn't read the file at all. This is where most beginners feel stuck. The SVG format is perfect for vector graphics but embroidery machines don’t read shapes the same way. They need stitch commands, directions, underlay, density, and trim information.

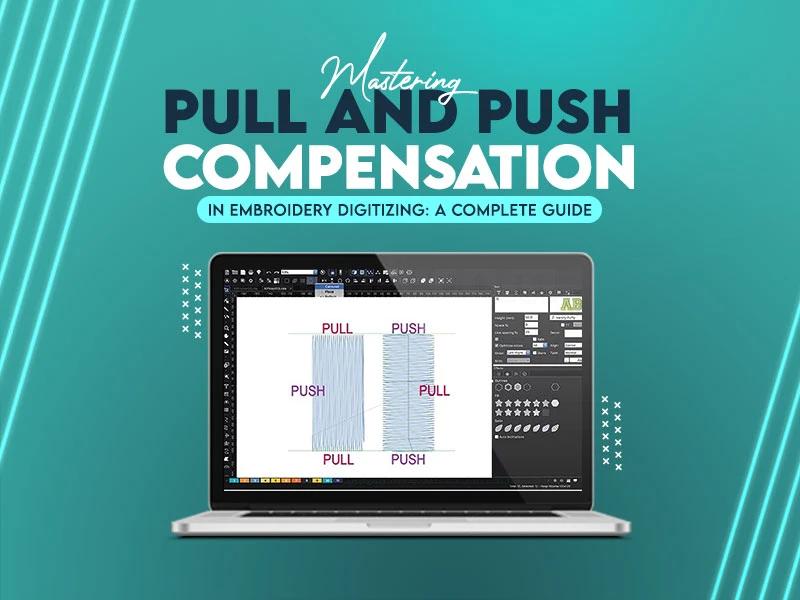

If you have been digitizing for a while, you already know one thing very clearly. A design can look perfect on the screen but once it gets stitched, the shapes shift, outlines go off, small letters close up and fill areas stretch. Many digitizers face these issues every single day. Most of the time, the root cause is the same, that is, pull and push distortion.

Pull and push distortion is something that every digitizer faces, no matter how simple or complex the design is. The challenge becomes even bigger when you work on thin columns, curved shapes, small text or detailed logos. Without the right compensation, even a well-digitized file looks uneven or out of proportion after stitching.

Now, let's understand this guide.

When people try 3D puff embroidery on hats for the first time, they expect a clean raised finish. But in many cases, the foam shifts, the stitches break, the design looks flat or the hat gets ruined. These problems make the process stressful, especially when you are working on hats with complex designs. The fact is, 3D puff embroidery on hats only turns out right when the design, machine, foam and stitching all work together.

This guide covers everything in a simple and practical way so you can get a bold, smooth and clean raised look every single time.

If you have ever done embroidery on different fabrics, you know the stabilizer can make or break your project. One design turns out nice but the next one gets puckers or the stitches pull the wrong way. A lot of people get confused because every fabric acts differently. Some stretch, some are very thin, and some move a lot inside the hoop.

This happens over and over when you are not sure what stabilizer to pick. One small mistake wastes threads, fabrics and of course time. Selecting the right stabilizer is the most important step in embroidery. When the backing is correct, the design looks clean, sharp and professional but when the stabilizer is wrong, it ruins your design, fabric and everything.

In this blog, you will learn which stabilizer works best for different kinds of fabrics so you can stop the common problems and get the desired results.