Wait, if you are looking for professional digitizers who digitize your embroidery designs professionally, always remember True Digitizing because we provide professional embroidery digitizing servicesin the USA and worldwide. We have 100% satisfied customers.

Grow your embroidery digitizing business with us, no matter if you want to digitize your embroidery patches, 3d puff embroidery designs, applique, chenille, or more. Contact us today or fill out the form, our team will contact you soon, and then you will get the cheapest embroidery digitizing services you need.

Water-soluble stabilizer

Batch master

Fabric

Patch twill

Heat n bond ultra

Curved tip scissors

The stabilizer needs to be water soluble and a violin, it is kind of a medium woven stabilizer that's really easy to use.

Another one would be batch master, Batch master looks and feels a little bit like a thin vinyl, it can be torn away from the outer edge. it does really well.

What do you also need? Of course, fabric, and the important part of the fabric is that you choose something that will hold up to the embroidery without puckering.

Another essential material is patch twill, patch twill has a shiny polyvinyl backing, and in the front, the fabric has a really beautiful sheen to it, it is very smooth when you stitch on it. It will hold up to the stitches just beautifully, also usable is regular twill as long as you reinforce it with, maybe woven fusible interfacing medium weight. You can also use quality cotton, but in all cases always be sure that it's something that won't pucker when you put the embroidery on top.

Lastly, you will need some kind of bonding agent so that you can place the finished embroidered patch onto the item that you want to have it on. Use Heat n Bond Ultrahold.

You are going to hoop your stabilizer, and the first color that you stitch will be stitched directly onto the stabilizer. A darker color is used so it is visible as the outline of the patch.

You are going to hoop your stabilizer, and the first color that you stitch will be stitched directly onto the stabilizer. A darker color is used so it is visible as the outline of the patch.

Once the patch outline is stitched, take your pre-cut piece of fabric and place it over the outline please make sure all stitches are covered nicely. Secure it with a couple of pieces of tape before returning it to your machine.

Your machine will now tack down the piece of fabric, similar to how it would do with a design.

Take your curved tip scissors and cut off the excess fabric from the outside of the tack-down stitches. Try to get close, but don't worry if you cut into the thread, as it is a triple bean stitch.

Take your curved tip scissors and cut off the excess fabric from the outside of the tack-down stitches. Try to get close, but don't worry if you cut into the thread, as it is a triple bean stitch.

Trimming while the fabric is in the hoop can be tedious. Also you can use a PDF template included with your download, cut it out, and use it as a guide to pre-cut your fabric.

If you pre-cut your fabric using a template, place it inside the placement guideline. Apply a small amount of adhesive spray before placing it to ensure it does not move.

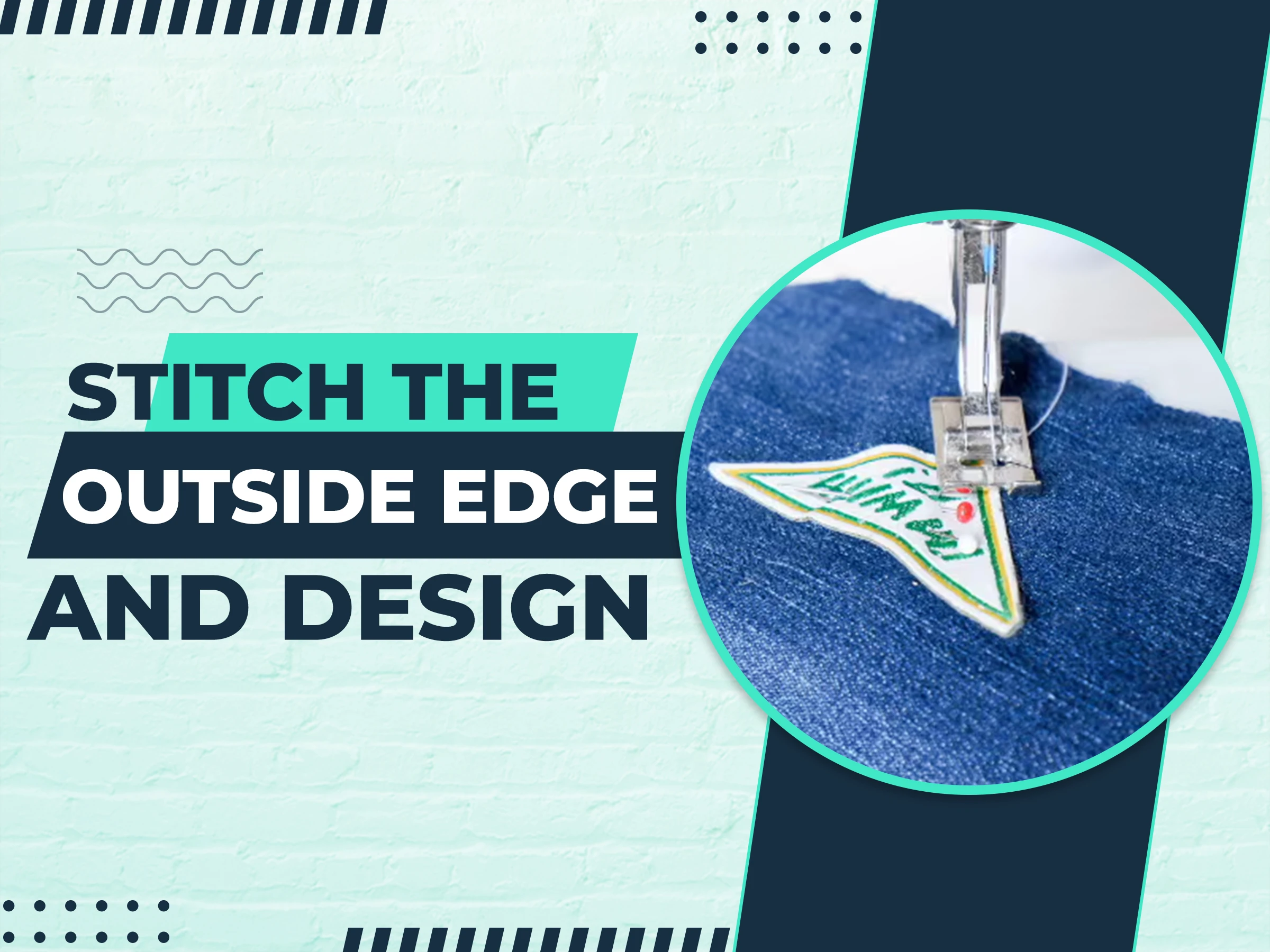

Return the fabric to the machine, which will stitch the outside edge of the patch. Follow the machine prompts to stitch the center design.

Return the fabric to the machine, which will stitch the outside edge of the patch. Follow the machine prompts to stitch the center design.

Once the design is stitched, unhoop the patch and remove the stabilizer. Trim close to the edges and remove any excess stabilizer using a Q-tip or damp rag. Let it dry completely.

.webp)

Choose a suitable backing to ensure the patch can be adhered to an item. You can use a template or trace the finished shape on an ultra-hold sheet to determine the cut area.

If making multiple patches, use a cutting machine along with the provided SVG file for efficient cutting.

Follow the instructions on the outer hold to fuse the backing to the patch. Hold the iron in place long enough to ensure proper adhesion.

.webp) Patches can be placed on caps, totes, pockets, and other items without needing a hoop. Let the adhesive dry, then remove the paper backing.

Patches can be placed on caps, totes, pockets, and other items without needing a hoop. Let the adhesive dry, then remove the paper backing.

Use a pressing cloth if needed, fold extra fabric, and press down firmly, especially along the edges. If possible, turn the item over and press from the back as well, ensuring strong adhesion without burning the fabric.

Lastly, pressed firmly and fully adhered, your embroidered patch is ready to be used on any item of your choice.

Lastly, pressed firmly and fully adhered, your embroidered patch is ready to be used on any item of your choice.

I hope you got it every step, making patches is not difficult. If you want to make embroidery patches, you require some important supplies, with these required supplies and the proper guidance you will make beautiful embroidery patches for individuals, large organizations, and others. So don't waste your time, start making patches today. And if you face any problems during the patches making process then contact us, we will help you. We create stunning patches for our customers. Trust true digitizing and we will never break your trust.

Thank you for reading.

Nick William has been immersed in the world of embroidery digitizing for over 20 years, earning 25 industry awards throughout his career. As a 3rd generation embroidery expert, Nick’s journey started in his family’s workshop, where he learned the art of digitizing before the rise of modern software. He has worked with leading commercial embroidery businesses and has shared his expertise with over 75,000 home and professional embroiderers. As an author at True Digitizing, Nick is passionate about teaching others how to create beautiful, precise designs through easy-to-follow tutorials and expert advice.

Categories

How To Create A Vector File: Step-by-Step Guide

15-04-2025

What Is A Vector File? Everything You Need To Know

14-04-2025

Best Janome Embroidery Machines You Need to Check Out in 2025

11-04-2025

Custom Embroidery Digitized Designs For Hoodie Lovers

10-04-2025

Best Embroidery Patches For Your Clothes

10-04-2025

Professional Online Photo Digitizing Services Provided by True Digitizing

09-04-2025

Best Babylock Embroidery Machines For You

09-04-2025

Barudan Embroidery Machines: From Beginners to Professionals

04-04-2025

Custom Sweatshirt Embroidery Digitized Designs By True Digitizing

03-04-2025

Why Brother Embroidery Machines are the Best Choice for Embroiderers?

27-03-2025